When using a fiber laser cutting machine for workpiece processing, slags may occasionally appear. Many people mistakenly assume this is due to equipment quality, but that is not the case. We’d like to discuss the causes of slags, preventive measures, and solutions below.

What Are Slags?

Slags refer to excess residual particles left on the surface of metal products during processing. If a workpiece has slags after processing, it is usually deemed defective and requires additional treatment.

How Are Slags Formed?

A laser cutting machine cuts materials by focusing a laser beam onto the surface of a workpiece, causing the material to vaporize or melt. During this process, auxiliary gas plays a critical role by blowing molten residues off the cutting surface. If the gas purity is insufficient or operation parameters are improperly set, residues can cool and stick to the cutting edge, resulting in slags.

Key Factors Affecting Slag Formation

- Auxiliary Gas Purity: Auxiliary gas is essential for removing molten residue from the cutting surface. Insufficient gas purity directly contributes to burr formation. It is recommended to use high-purity gas and avoid cylinder-stored gas, as its purity often decreases after multiple fillings, leading to inefficiency and waste.

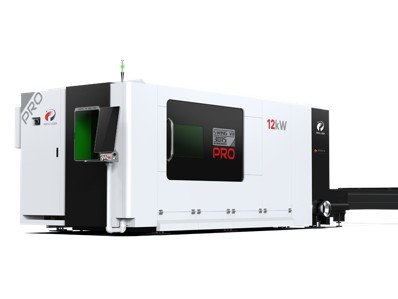

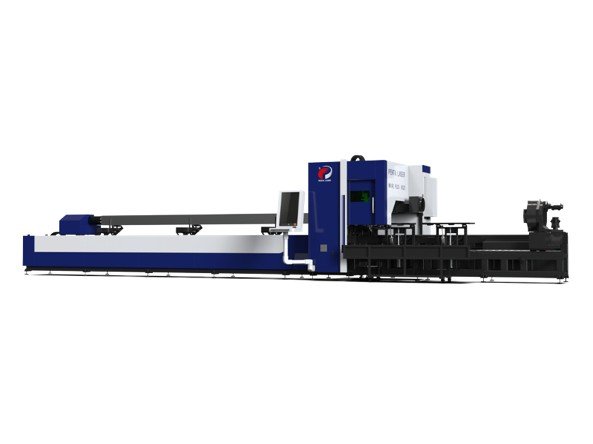

- Equipment Quality and Maintenance: The quality of the laser cutting machine determines its cutting stability and precision. Prolonged operation or inadequate maintenance may degrade performance and affect cutting results.

- Cutting Parameter Settings: Parameters such as laser power, focus position, and cutting speed directly influence cutting performance. Incorrect settings significantly increase the likelihood of burrs.

- Operator Expertise: Fiber laser cutting machines require experienced operators to adjust parameters and ensure optimal equipment performance.

How to Resolve Slag Issues During Processing?

- Check Laser Power Output: If the laser power output is insufficient, verify whether the machine is functioning correctly. Perform maintenance if necessary or adjust the output parameters accordingly.

- Adjust Laser Focus Position: Misalignment of the laser focus position can negatively impact cutting quality. Adjust the focus to ensure precision.

- Replace High-Purity Auxiliary Gas: If the gas purity is found to be inadequate, switch to a higher-purity auxiliary gas to improve cutting results.

- Adjust Cutting Speed: Slower cutting speeds may lead to quality issues. Increase the speed appropriately to minimize burr formation.

- Allow the Machine to Rest: Prolonged continuous operation may cause overheating or performance degradation, leading to burr issues. Turn off the machine periodically to allow it to cool before resuming work.

As a precision device, a fiber laser cutting machine requires meticulous operation and maintenance to avoid processing defects. By ensuring equipment is in good condition, using high-purity gas, and properly setting operational parameters, burr formation can be effectively prevented. Systematic maintenance and standardized operation not only enhance cutting quality but also extend equipment lifespan and boost production efficiency.

If you would like more advice on optimizing your fiber laser cutting machine, Gleam Machinery is ready to provide you with remote or online technical guidance. Contact our team of experts and let us help you take your cutting process to the next level with our professional services!

📞 : 312-257-7289